ViGYAN - Low Speed Wind Tunnel

Designed and built in-house, ViGYAN's Low Speed Wind Tunnel is located at our main ViGYAN business site in Hampton, Virginia, in the Aero-Fluids Laboratory building behind our offices in the Langley Research and Development Park. The low-speed, open-return-design tunnel has been in operation since 1988, serving the aerodynamic testing requirements of government agencies and commercial customers, in addition to supporting ViGYAN's own on-going, internal research and development.

The facility has recently undergone a major renovation of its model-support, electronics, and data-acquisition systems. The Tunnel's state-of-the-art, automated systems provide excellent force and moment, pressure and flow-visualization capabilities.

Facility staffing includes engineers, model builders and technicians, model systems engineers, and instrumentation/data acquisition and reduction specialists.

Capabilities & Expertise

The ViGYAN Wind Tunnel, built in 1985, is the only commercially available wind tunnel facility in the Hampton Roads region outside of NASA Langley. It has been a part of numerous advanced research and development efforts for NASA and ViGYAN. These include:

- Dr. D. Rao, one of the ViGYAN founders, worked on and received numerous patents during the 1980's and 90's in the area of vortex flows, vortex flaps, and delta wing aerodynamics. Much of this work was the result of ViGYAN's Low Speed Wind Tunnel.

- All of the U.S. Mars landers supported by the NASA Langley Entry Descent and Landing (EDL) team have been tested in the ViGYAN Wind Tunnel. These include Mars Pathfinder, Mars Exploration Rovers (Spirit and Opportunity), Mars Phoenix, Mars Science Lab (Curiosity), and Mars Insight (2018).

- ViGYAN has been at the forefront in the development of advanced damping systems for sting-mounted wind tunnel models. Originally developed in the ViGYAN Wind Tunnel under an Air Force SBIR, these systems have been continuously improved and implemented in both NASA and Air Force wind tunnel facilities.

- Our most recent upgrade o the facility includes a Rotor Test Cell, used to develop the various pro[eller systems (PTS, Open Rotor, Rear Cone Thruster). The cell offers a safe enclosure for testing high-RPM propellers, data acquisition for measuring performance, and endurance testing.

- Current research initiatives include the Digital Bridge thermal anemometry system, advanced electric motor propeller testing hardware, a unique free-flying autonomous ProbBot wind tunnel survey system, and the Active Ride Improvement System (ARIS) for mitigating turbulence effects on small aircraft.

Magenn Power Inc., has created the Magenn Air Rotor System, an inexpensive, lighter-than-air, tethered wind turbine that generates electrical energy by rotating about a horizontal axis in response to active airflow at 60 to 1,000 feet in altitude.

ViGYAN provides an extensive array of associated support, including wind tunnel model fabrication, instrumentation and electronics, test engineering, and aerodynamics research expertise and computational fluid dynamics.

Tunnel and other engineering services are competitively priced and available via company purchase orders, credit card, or via the TEAMS support services contract at nearby NASA Langley Research Center.

Typical Wind Tunnel tests over the past several years have included:

- Architectural Screens

- Instrument & Sensors

- Spacecraft

- Typographical Models

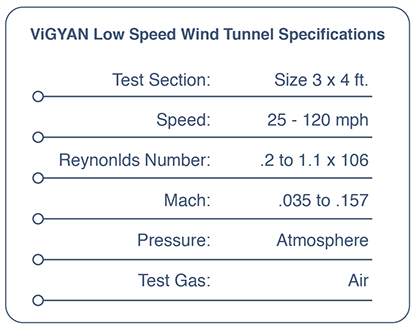

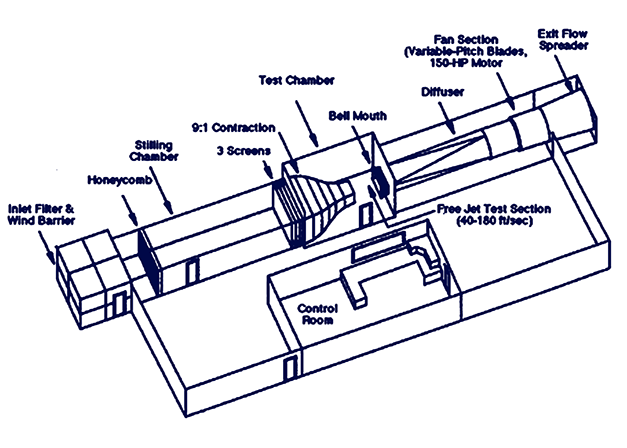

ViGYAN's Low Speed Wind Tunnel is a conventional, straight-through, open-return layout powered by a variable-pitch, multi-blade axial fan located at the exit, providing a precisely controlled airspeed in the test section, ranging from 40 to 180 feet per second (27 to 122 miles per hour).

- Inflatable Structures

- Aircraft

- Buildings

- Ground Vehicles

Ambient air is drawn through an inlet cage lined with densely woven filter material, which also serves to suppress external wind disturbances. The flow passes through a screened honeycomb, a long settling chamber, three woven, seamless, anti-turbulence screens and, finally, a nine-to-one contraction, before being discharged into the test chamber as a highly uniform, rectangular, cross-section jet four feet in width and three feet in height.

After traversing a five-foot length, the jet is collected by a bell-mouthed diffuser, conveyed through the fan and exhausted to atmosphere. These flow-conditioning measures reduce the turbulence level at the model position to less than 0.1 percent. Sphere tests have established the turbulence factor to be under 1.05.

Areas of Expertise & Notable Projects

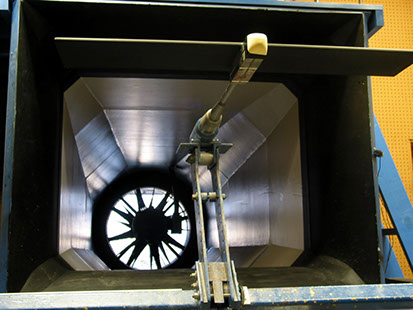

The walk-in test chamber surrounding the test jet is large enough to accommodate two or three observers, with ear protection the only requirement. The free-jet configuration allows instant access to the model and facilitates flow visualization and photography from a variety of viewpoints. Alternate wall configurations (e.g., solid, semi-open, ground board, etc.) can be readily installed for special test requirements.

For models requiring changes in angle of attack or yaw angle, the model support mechanism allows the model attitude to be varied in the range of -10 to +90 degrees of pitch and -20 to +20 degrees of yaw, accurate to 0.1 degree. It features a closed-loop control system integrated with the data acquisition system for repeatable, efficient conduct of testing operations.

Typical Wind Tunnel tests over the past several years have included:

Architectural Screens

Instrument Control & Sensors

Spacecraft

Architectural Screens - ViGYAN has conducted drag testing for Cambridge Architectural to measure drag on architectural screen materials to better assess wind loads on the materials incorporated into building designs.

A robust instrumentation and control-system and a LabVIEW-based data acquisition system provides measurement and reduction of tunnel conditions, balance loads and other analog channels. This system is part of a control room network with workstations for customers to view, plot and process data immediately after each run, as well as allow access to previous runs, tests or customer-supplied comparison data.

ViGYAN supported the Mars InSight Lander NASA study to help in the analysis and prediction of the vehicle's entry aerodynamics...

Typographical Models

Inflatable Structures

Aircraft

GE Transportation ViGYAN has tested heat sensors for GE Transportation to better understand airflow and to help develop improved internal architectures. The sensors are typically installed on railroads to look for bearings that become hot as trains transverse the tracks.

Buildings

ViGYAN has evaluated The Magenn Air Rotor System (MARS) three versions of this inflatable wind turbine concept. The purpose of the tests has been to assess performance, explore new ideas, understand the pertinent aerodynamics, and develop parametric trends. The ultimate goal was to assist Magenn in design of an optimum configuration and calibration of the company's empirical prediction tools.

Tunnel Testing Techniques

GE Transportation ViGYAN has tested heat sensors for GE Transportation to better understand airflow and to help develop improved internal architectures. The sensors are typically installed on railroads to look for bearings that become hot as trains transverse the tracks.

Ground Vehicles

GE Transportation ViGYAN has tested heat sensors for GE Transportation to better understand airflow and to help develop improved internal architectures. The sensors are typically installed on railroads to look for bearings that become hot as trains transverse the tracks.

ViGYAN has also been involved in a number of projects to develop advanced tunnel testing techniques. These efforts have included the development of forced oscillation, rotary balance and other dynamic testing methods.

In addition, our engineers have supported a number of efforts utilizing powered wind tunnel models (both static and dynamic) using high-pressure air and electric motors. Our staff has also supported advanced measurement, diagnostics and an extensive array of instrument systems.

GE Transportation ViGYAN has tested heat sensors for GE Transportation to better understand airflow and to help develop improved internal architectures. The sensors are typically installed on railroads to look for bearings that become hot as trains transverse the tracks.

Data-reduction procedures, instrumentation and balance wiring/connectors, and data formats are based on those widely used at NASA Langley Research Center (LaRC) to facilitate easy movement of models, balances, and data between ViGYAN and LaRC. Statistical process control procedures are also in place to monitor data quality in the facility; this information is provided to customers as it is available and analyzed.

A fully equipped electronics and instrumentation laboratory is located in the facility to support testing and special requirements. The adjoining shop supports fabrication of most of the wood, sheet-metal and fiberglass models tested. It also provides model modification services to customer test hardware. In addition, ViGYAN has cooperative arrangements with specialized, high-precision model fabricators in the area.

Cost & Staff Support

Cost and Staff Support

The ViGYAN Wind Tunnel rate is reasonable and competitive, with a minimum occupancy of eight hours. The comprehensive price includes:

- Tunnel operations

- A full-time tunnel operator

- A data acquisition system operator

- Instrumentation/electronics support

- Test engineer support as needed

- Data quality engineer support

- Post-test-data report, including data-quality analysis

- Customer access to online reduced data engineering workstation

- Electronic copies of data, photographs, test video and run logs

Most tests will require some pre-test model setup and test preparation by the model technicians and/or electronics specialists. The cost of this (either by fixed amount or by actual hours) is normally quoted prior to the test and is based on the level of complexity of the test.

Additional (optional) support from ViGYAN staff can be provided at additional cost and includes the following:

- A full-time test engineer to monitor tests, data, and preliminary results.

- Full-time aerodynamicists or other researcher specialists to analyze results, recommend test and/or research direction, or provide more extensive post-test reporting.

- Computational fluid dynamics (CFD) support before or after testing to assist in test program planning or data analysis.

- Test engineering support for testing in other facilities.

- Design and fabrication of test models, specialized electronics, or other test support hardware.

Tunnel charges and payments can be arranged by any of the following methods:

- Advance payment by check or credit card

- Company purchase orders

- The NASA Langley TEAMS task order contract, NNL07AA00B

Scheduling of the tunnel is done on a first-come, first-served basis as confirmed by advance payment, issuance of a purchase order, or issuance of a task. Scheduling in advance is preferable and assures priority in meeting the customer's test objectives.

As noted earlier, we can also access NASA Langley Research Center wind tunnels through an existing Space Act Agreement.

Copyright © 2008 - 2022 VIGYAN Inc. | Web Official: Richard White | Webmaster: Timothy Tepper | Site Curator: Jonathan Behun | | Privacy Policy